www.tenmagnetics.com

|

|

|

|

|

|

Formulation development

Material Content Research, Reduce the Heavy Rare Earth Material. |

|

|

|

Magnetic material, finishing machining, electroplating technology

The material has undergone various performance improvements such as continuous sintering, casting temperature control, grain refinement, and dysprosium diffusion. Advanced equipment such as vacuum continuous sintering furnace, vacuum flake furnace, hydrogen crushing furnace, etc. |

|

|

|

|

The magnets technology is standardized in requirement

with high detecting technology:

The professional testing team analyzes properties such as size, magnetic properties, and magnetic flux,ect. According to customer specifications and operating temperature, calculate the PC value, select or customize the grade to help customers reduce costs. The detection data can be analyzed and controlled before the forming and sintering stages.According to the customer's assembly characteristics, the uniformity and N/S pole fluctuation of the magnet can be controlled. |

|

|

|

|

|

|

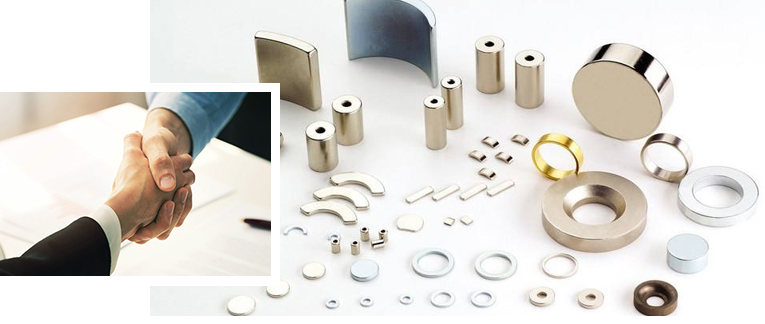

Our Team

We have a team of professional engineers to study the correlation between motor parameters and magnetic steel. We have a professional foreign trade SALES TEAM to provide you with considerate service, proficient in export rules and related operations. We have an excellent and conscientious workshop team to do the detailed work of each product for you,welcome to inquiry us. |

|

|

|